Differences in the angle of fabric and Percy

Angle irons are classified into two types based on shape: equal leg angle irons and unequal leg angle irons. Equal leg angle irons are often used in applications where unequal leg angle irons cannot be utilized. Angle irons are also categorized by production method into two types: fabricated and pressed

?What is an Angle Iron

Angle irons are classified into two types based on shape: equal leg angle irons and unequal leg angle irons. Equal leg angle irons are often used in applications where unequal leg angle irons cannot be utilized. Angle irons are also categorized by production method into two types: fabricated and pressed. In the following, we will discuss each of these methods in detail.

A common question among individuals is how to identify angle irons. Two important parameters for identifying different types of angle irons are the dimensions of the legs and the thickness of the product. For example, an angle iron with dimensions of 50*50*3 means that the size of the legs is 50 mm by 50 mm and the thickness of each leg is 3 mm. It's worth noting that the sizes of angle irons range from 2 to 15 cm.

Applications of Angle Irons

In general, angle irons are used to create connections, including the connection of beams to columns and the connection of columns to plates in the foundations of steel structures. Additionally, angle irons are used in the construction of large iron door frames, in the fabrication of steel structures, for columns and trusses, and also in the tower manufacturing industry.

?What is Pressed Angle Iron

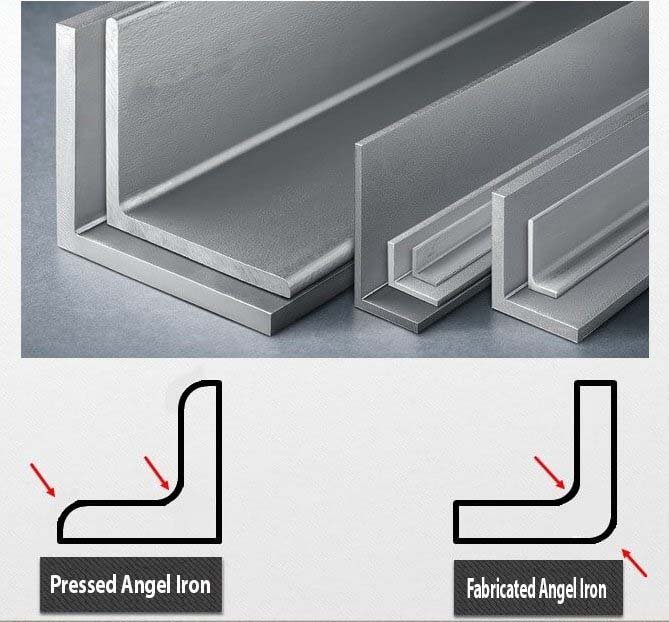

Pressed angle iron is one of the types of angle irons used in construction and various industries. The production of pressed angle iron is based on cold-rolled profiles. To manufacture pressed angle irons, steel sheets are first cut, and after cutting, these sheets are placed in a roll-forming machine for shaping. During this process, the sheet is bent and takes the shape of an angle iron. The roll-forming machine consists of several gearboxes and has the ability to shape steel sheets of any thickness and length. Fabricated angle irons are produced according to the GOST 8510 standard and can be identified by their rounded corners.

?What is Fabricated Angle Iron

The production method for fabricated angle iron is hot rolling. In general, it can be said that each of these angle irons has fundamental differences based on their production processes. To make this type of angle iron, a steel billet or bloom is first transferred to heating furnaces with specific dimensions. The transfer of the billet through the rollers in the furnace reduces its thickness and increases its length until it ultimately becomes a profile in the shape of an angle iron. This type of angle iron is manufactured according to the German DIN 1022 standard. Overall, the quality of fabricated angle iron is higher than that of pressed angle iron. To distinguish between these types of angle irons when purchasing, it is essential to be informed about each product so you can select the best, most suitable, and highest quality option.

Differences Between Pressed and Fabricated Angle Iron

One of the main differences between pressed angle iron and fabricated angle iron is the method of production. As previously mentioned, fabricated angle iron is produced through hot rolling, while pressed angle iron is produced through cold rolling. Fabricated angle irons pass through the production stages in the form of angle irons from the very beginning of the manufacturing process. Additionally, these two products can be easily distinguished by their appearance; some of them have equal legs, while others have unequal legs.

Fabricated angle iron is directly shaped in the production line, and the forming and pressing processes are carried out on this type of angle iron; whereas, pressed angle iron, as the name indicates, undergoes a pressing process that involves applying pressure and shaping. It is made from steel sheets of 6-meter lengths and is converted into angle iron after being bent.

:Prices of Angle Irons

The price of angle iron, like other steel profiles, depends on various factors. For instance, the price of this product is influenced by the price of sheets as well as supply and demand levels. It's important to note that market fluctuations significantly impact the final price of this product; meaning if the demand exceeds the supply, market conditions will become unstable, and the price of angle iron will change. To calculate the weight of angle iron, three parameters—length, thickness, and leg size—must be determined, as these three factors have a considerable impact on the price of angle iron.

User Comments